» Effizient, innovative und outstanding

When heavy loads generate excitement, new ideas are formed.

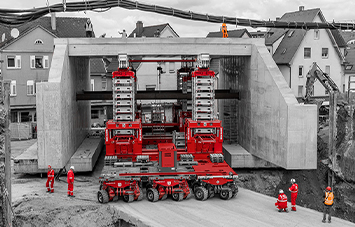

For the first time, Riga Mainz combined Scheuerle SPMT remotecontrolled heavy-duty transporters with a vessel bed and strand jacks to effectively replace several railway bridges. This in-house development has earned us a prestigious award from the German Federal Working Group for Heavy Transport and Crane Work (BSK) in the category „Assembly of the Year 2020“.

We are now setting a new milestone by improving our heavy-duty assembly segment with two enhanced

lifting and moving systems with a capacity of up to 4,000 tons.

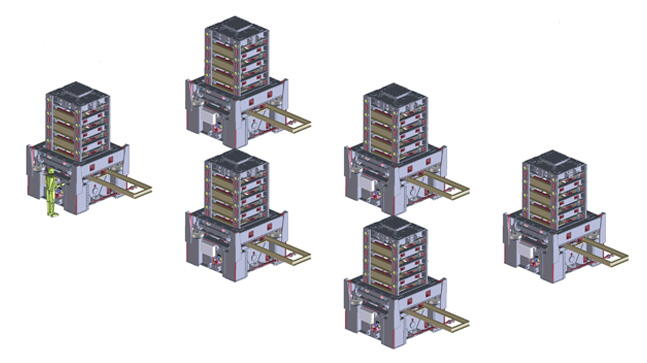

Power Lift Tower

» Lifting in a new dimension

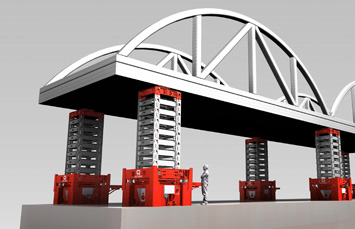

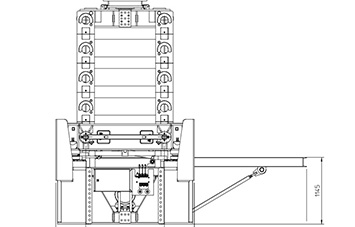

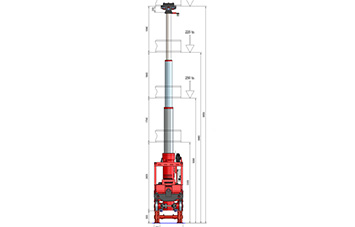

The Power-Lift-Tower system consists of up to eight individually positionable towers with a total lifting capacity of 4,000 tons. The time-consuming work involved with laying

vulnerable hydraulic lines is no longer necessary – a 400V/32A power cable is all that is

needed to connect each tower. The entire control system can be operated via a wireless

remote control, where all the relevant data can be called up at any time. Alternatively, operation is also possible by cable.

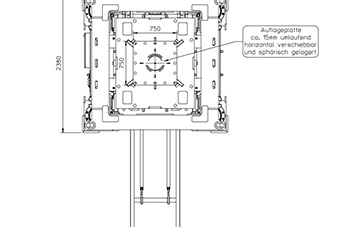

Redundant position sensors ensure that the system is raised/lowered evenly, and the square support plates (750mm) are equipped with a spherical central bearing for linear

lift. In addition, the base and head plates have numerous mounting options for accessories or stable installation on our SPMT modules.

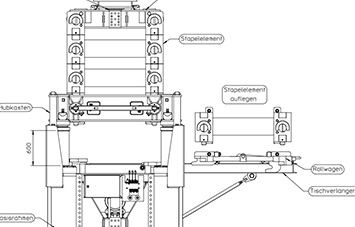

» Process / Handling

- 8 hydraulic lifting towers, each with a 500-ton lifting capacity

- Simultaneous lifting of the towers is controlled electronically

- The system can also be operated in a 2 x 3 combination

- Optionally expandable to a maximum of 8 towers as group, or in a combination of 2 x 4 towers

- Load supported by head plates in a spherical bearing

- Mechanical locking of stacking elements

- The load is in a resting position on the mechanically secured lifting tower; therefore, intermediate storage of the load on the towers is possible without additional safety devices

(group of 8)

Engineering in the planning and execution phase

» Your partner for complete solutions

We organise and plan the receipt of plant components from the manufacturer to the fully assembled plant with acceptance documents.

Chemie/Petrochemie

- Project management

- Safety analyses

- Transport and crane technology

- Heavy-duty transport & lifting

- Assembly technologies

- Installation of new factory sites

- Machine and equipment assembly

- Shutdowns

- Framework agreements

Energie

- Project Management

- Safety analyses

- Lifting - moving - transporting

- Assemble / installation

- Expansion or new construction of energy plants

- Dismantling and deconstruction

Industrie

- Project Management

- Safety analyses

- Transport and crane technology

- Heavy-duty transport & lifting

- Assembly technologies

- Relocation and assembly of new factory sites

- Machine and equipment assembly

- Service

On schedule with high standards

We prepare and carry out our complete scope of services with great care. In doing so, we guarantee on-time and optimal implementation of our services in compliance with the highest safety standards.

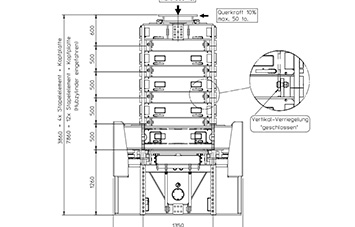

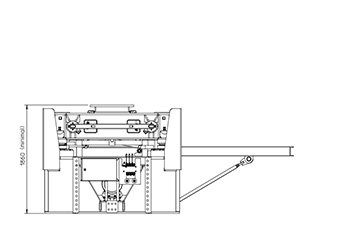

Lifting gantries

» Powerful performace with compact dimensions

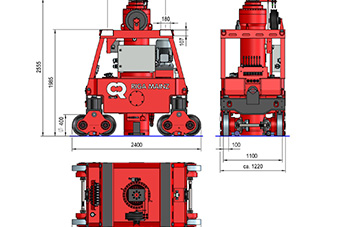

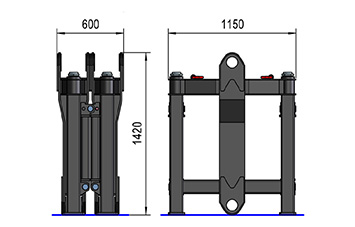

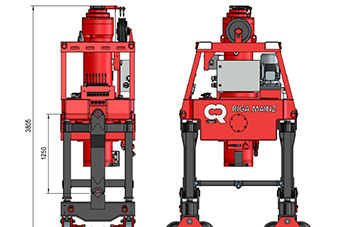

The new GHS 3-1000 lifting mast is available for moving heavy loads of up to 1,000 tons. The system consists of four three-stage extendable cylinder towers and is mounted on double travel rails with a width of 1,200 mm. A special feature of the modular system is an additional height increase that can be installed in the base frame (1,250 mm), which provides a total height of up to 10,100 mm (without gantry girders). For smooth parallel travel, the system‘s base frames are equipped with a track guide and are mechanically

connected in pairs. In this new generation, simultaneous lifting is monitored electronically, which facilitates precision work. The system is controlled via a wireless remote control.